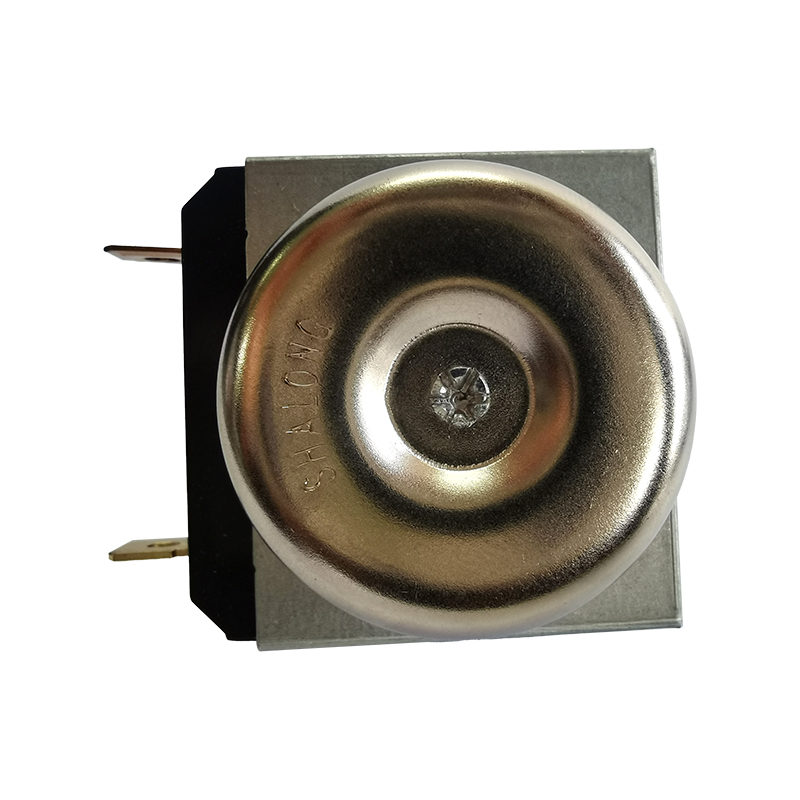

Mechanical timers are widely used in daily life and industrial production due to their ease of operation, stability, and durability. However, safe use of mechanical timers is crucial. The direct conclusion is: when using mechanical timers, strictly adhere to rated voltage and load requirements, avoid humid environments, regularly inspect mechanical components, and ensure correct installation and wiring to prevent electrical faults or accidental damage.

Strictly Adhere to Rated Voltage and Load Requirements

Each mechanical timer has a clearly defined rated voltage and load limit. For example, a common household mechanical timer has a rated voltage of 220V and a rated power of 1500W. Overloading a mechanical timer can not only cause it to overheat and damage internal parts but may also lead to a fire. Always check the power rating of the appliance before use and select a timer model that matches the load.

For example, if a 1500W mechanical timer is connected to a 2000W heater, prolonged operation may cause the internal springs to overheat, gears to be damaged, or even trigger a safety accident.

Avoid Humid and High-Temperature Environments

Mechanical timers are precision mechanical devices, and their internal gears and springs are very sensitive to moisture. Prolonged use in humid environments may cause metal parts to rust, poor contact, and even short circuits. It is recommended to install mechanical timers in a dry, well-ventilated location, avoiding proximity to water sources or bathroom environments.

High temperatures also affect the lifespan of mechanical timers. For example, prolonged use in environments exceeding 50°C may cause the internal lubricant to dry out, leading to gear jamming.

Regular Inspection and Maintenance

To ensure the safety and accuracy of the mechanical timer, it should be inspected and maintained every 3-6 months. Inspection items include:

- Checking for damage or deformation to the casing

- Checking the smoothness of the knob

- Checking the security of the power cord connections

- Checking for any abnormalities in timing accuracy

If any abnormalities are found, stop using the timer immediately to prevent accidents. In industrial settings, infrared thermometers or current monitoring devices can be used to monitor the mechanical timer's operating status in real time.

Correct Installation and Wiring

When installing a mechanical timer, wiring must be done correctly according to the instruction manual. The live wire and neutral wire must not be reversed. Loose wiring can lead to poor contact, causing arcing or electric shock accidents. For home use, it is recommended to use mechanical timers with protective covers to reduce the risk of accidental activation.

In industrial applications, mechanical timers should be fixed to a dry, sturdy panel to prevent loosening due to vibration and potential equipment malfunction.

Avoid Prolonged Continuous Use

The spring-driven structure of mechanical timers is designed for intermittent operation. Continuous, overloaded use can accelerate mechanical wear. For example, if a household mechanical timer runs continuously for more than 24 hours, the internal spring may fail, leading to decreased timing accuracy. The correct approach is to set it to intermittent operation whenever possible, or to choose an industrial mechanical timer specifically designed for long-term operation.

The key to safe use of mechanical timers lies in adhering to rated load and voltage limits, avoiding humid and high-temperature environments, conducting regular maintenance and inspections, and ensuring proper installation and wiring. These measures can significantly reduce the risk of mechanical failure and safety accidents, while extending the lifespan of the mechanical timer. For both home and industrial users, safe use not only protects equipment but also ensures personal and property safety.

English

English 中文简体

中文简体