The core principle of automatic power cut-off in an oven mechanical timer is that the mechanical timing structure drives the internal switch contacts, and when the preset time is reached, the circuit power supply is automatically disconnected, thus realizing the safety control function of “power cut at time-up, automatic shutdown.” In essence, it is an electromechanical timing power-off control system with a mechanical structure as the core and electric drive as the power source. It does not rely on chip programs, but completes automatic control through physical structures.

Basic working structure of an oven mechanical timer

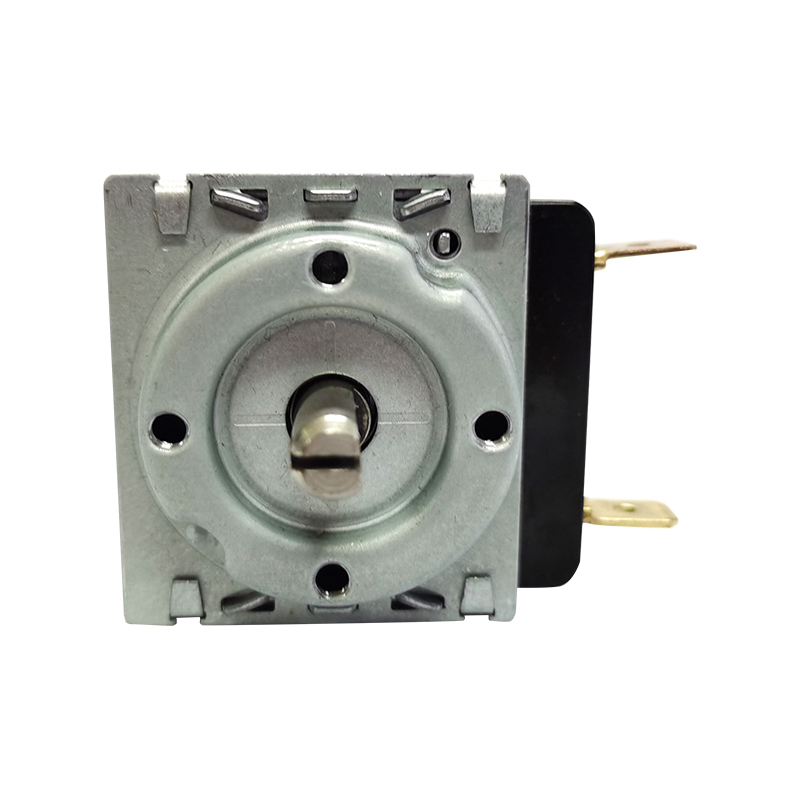

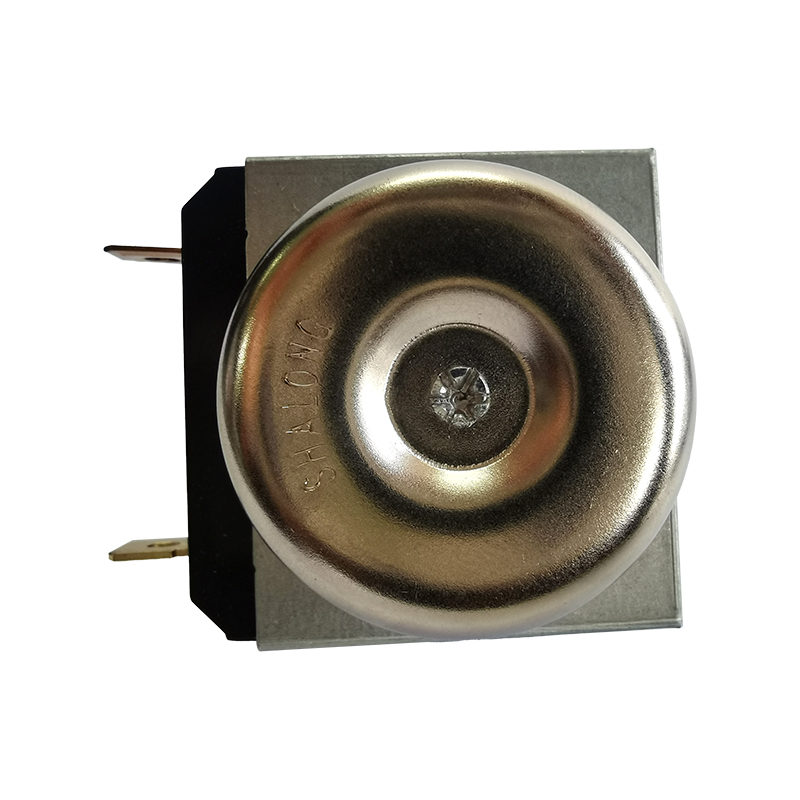

An oven mechanical timer is a typical electromechanical integrated device, mainly composed of the following structures: synchronous motor drive system, gear reduction transmission mechanism, time scale dial, mechanical cam structure, spring contact switch system, reset spring structure. These components together form a complete automatic power-off system of the oven mechanical timer.

Core principle of automatic power cut-off

Mechanical timing drive mechanism

After the oven mechanical timer is powered on: current drives the synchronous motor to rotate, the synchronous motor drives the gear system to operate, the gear system reduces speed for timing according to a fixed ratio, the time scale dial starts timing, the power grid frequency (50Hz/60Hz) becomes the timing reference, ensuring time stability.

Cam-triggered power cut-off structure

In the internal structure: a mechanical cam is set on the time shaft, the cam and the contact spring form a mechanical linkage, when the preset time point is reached → the cam pushes open the contact structure, the contacts separate → the circuit is disconnected → the power supply is cut off. This is the physical mechanism of automatic power cut-off of the oven mechanical timer.

Automatic power cut-off working process of the oven mechanical timer

Power-on start: synchronous motor timing, gear system transmission, time scale advancing, cam triggering mechanism action, contact disconnection, power circuit cut off, oven stops working, synchronous motor timing, gear system transmission, time scale advancing, cam triggering mechanism action, contact disconnection, power circuit cut off, oven stops working. The whole process is pure mechanical control logic + electric drive system, with no electronic program participation.

Safety problems mainly solved by the automatic power cut-off function of the oven mechanical timer

Prevent food over-baking, prevent equipment idling overheating, prevent electrical appliances overload operation, reduce fire risk, improve safety level. In household ovens and commercial baking equipment, automatic power cut-off is a basic safety control function.

Factors affecting the power-off accuracy of oven mechanical timers

Synchronous motor speed stability, gear machining accuracy, degree of mechanical wear, power supply voltage stability, long-term operation aging condition.

Comparison of power-off methods: oven mechanical timer vs electronic timer

| Comparison dimension |

Oven mechanical timer |

Electronic timer |

| Control method |

Mechanical contact power-off |

Relay / electronic switch |

| Drive method |

Synchronous motor |

Chip program |

| Power-off method |

Physical circuit break |

Electronic control disconnection |

| Anti-interference ability |

High |

Medium |

| Structural stability |

High |

Medium |

| Accuracy |

Medium |

High |

Application advantages of oven mechanical timers

Simple structure, low failure rate, not dependent on program systems, strong anti-electromagnetic interference ability, low cost, convenient maintenance, long service life. Therefore, they are still widely used in household appliances and basic commercial equipment.

Scenarios suitable for using oven mechanical timers

Household electric ovens, commercial baking equipment, simple industrial drying equipment, food heating equipment, constant temperature heating systems.

The automatic power cut-off of an oven mechanical timer is not achieved by electronic programs, but by the physical structural system of “synchronous motor timing + gear transmission + cam triggering + mechanical contact power cut-off.” Although this structure does not have high-precision intelligent control capability, it has significant advantages in stability, safety, and reliability. In oven equipment systems, the oven mechanical timer is not only a timing device, but also a core safety power-off control component, it plays a vital safety role in preventing overheating, overload, and misoperation.

English

English 中文简体

中文简体