The core components of this Small Size Precision Mechanical Timer are usually made of stainless steel or special alloy materials. These metals have good high temperature resistance and can maintain structural stability in a high temperature environment to avoid deformation or strength loss.

If some auxiliary components are made of plastic, ordinary plastics may soften or deform at high temperatures, thus affecting the accuracy of mechanical transmission. However, if the manufacturer uses high-temperature engineering plastics, the heat resistance can be significantly improved to ensure reliability under long-term high temperature use.

In addition, the choice of lubricant is also crucial. Ordinary lubricating greases are easy to volatilize or oxidize at high temperatures, resulting in increased friction and affecting timing accuracy, while high-temperature resistant lubricants (such as silicone-based or fluorinated greases) can effectively reduce this problem.

Metals and plastics will expand to varying degrees when heated, which may cause changes in gear meshing clearance or mechanical structure jamming. Precision-designed timers usually use a combination of materials with similar thermal expansion coefficients, or reserve appropriate tolerances in the structure to offset the dimensional changes caused by high temperatures. If the materials are not matched properly, high temperatures may cause the gears to mesh too tightly or too loosely, thus affecting the operating accuracy of the timer.

The structural design of high-temperature timers needs to consider heat dissipation and sealing. Good sealing performance prevents dust, moisture or corrosive gases in high-temperature environments from invading the interior, avoiding accelerated metal oxidation or lubricant failure.

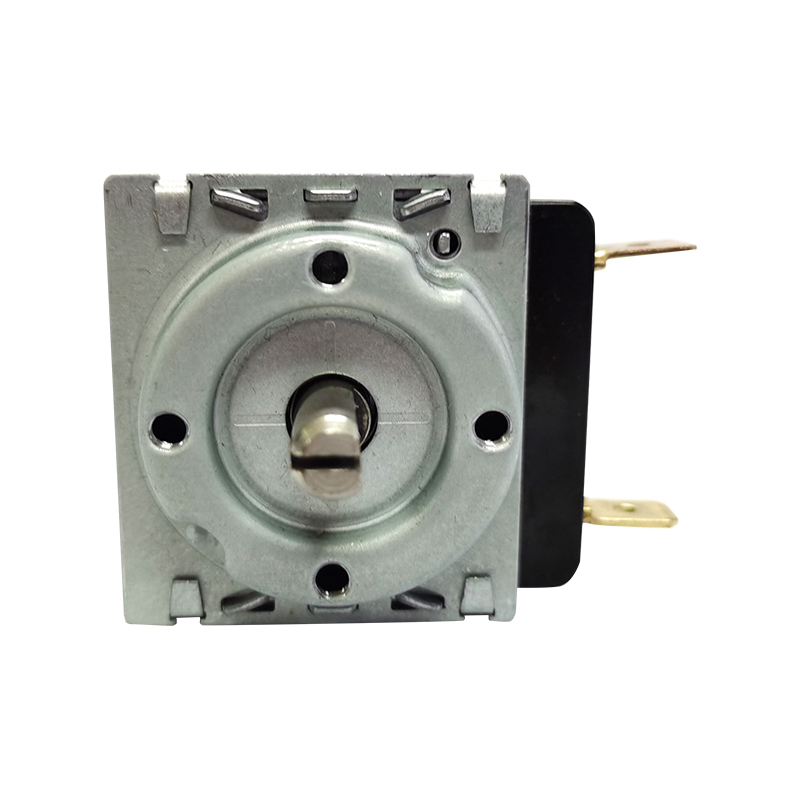

Some high-end timers use metal casings, using their thermal conductivity to help dissipate heat and prevent the internal temperature from continuing to rise. In addition, reasonable gear layout and force distribution can also reduce the impact of high temperature on mechanical transmission and ensure long-term stable operation.

Even if the material itself is resistant to high temperatures, long-term exposure to high temperatures may still have a cumulative effect on the timer. For example, metal springs or springs may experience stress relaxation or fatigue under continuous high temperatures, resulting in weakened elastic force and affecting the stability of timing power output.

If plastic parts are exposed to high temperatures for a long time, they may gradually age, become brittle or deform, resulting in structural looseness or functional failure. In addition, high temperatures may accelerate the degradation of lubricants, increase friction, and further affect accuracy.

English

English 中文简体

中文简体