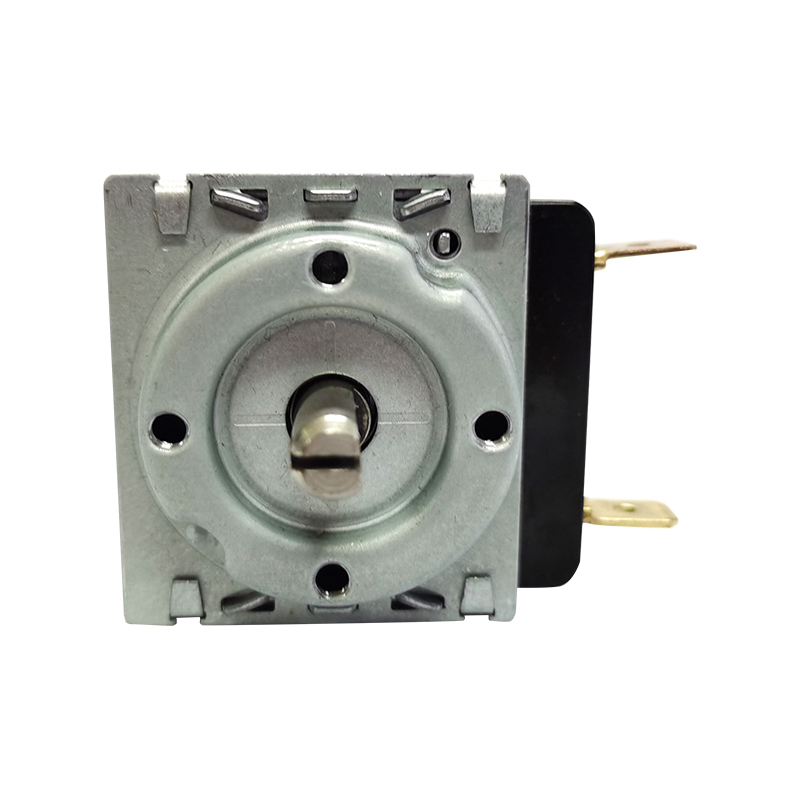

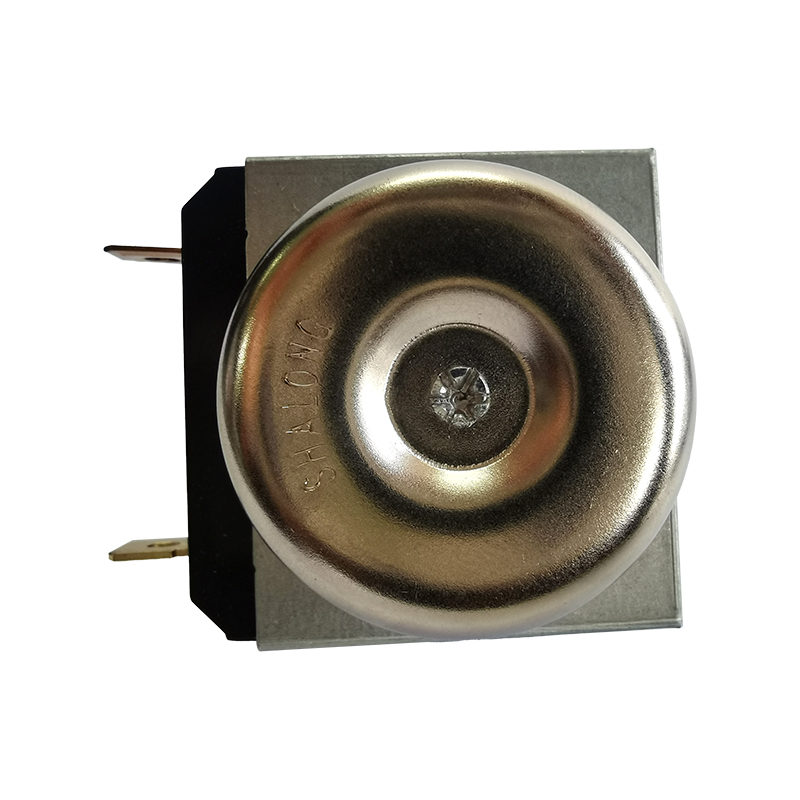

A high-quality oven mechanical timers not only provide precise timing control but also serve as a core component ensuring long-term, stable operation. However, even a well-designed product can be affected by a variety of factors.

1. Extreme Temperature and Thermal Shock

The inherent operating environment of an oven dictates that oven mechanical timers must withstand high temperatures.

- Sustained High Temperature: Prolonged exposure of electronic components and mechanical structures near the timer to high temperatures can accelerate the volatilization of internal lubricants and the aging of plastic parts, leading to increased friction in the transmission mechanism, ultimately affecting timing accuracy and the lifespan of the timer.

- Thermal Shock: The rapid temperature fluctuations caused by frequent oven openings and closings can cause components made of different materials to expand and contract differently. This stress can cause microcracks in internal gears or springs, a hidden risk for oven mechanical timers. Therefore, selecting high-temperature-resistant materials is key to extending their lifespan.

2. Humidity and Corrosion

High humidity or steam is a common problem in some industrial ovens or commercial kitchen environments.

- Humid Environments: Excessive humidity can cause rust in the metal components within a mechanical timer, especially the transmission gears and springs. Rust increases mechanical resistance, causing the timer to run inaccurately or even become stuck.

- Chemical Corrosion: Industrial ovens (such as paint curing ovens) or certain food processing equipment may generate corrosive gases or vapors, which can corrode the timer's casing and internal components, significantly shortening its lifespan.

3. Operating Force and Frequency

User habits have a direct impact on the lifespan of a oven mechanical timer.

- Excessive Force: Many users habitually turn the knob all the way down before turning it back when setting the oven timer. Excessive or rough operation can cause additional shock and wear to the delicate internal worm gear mechanism and zero return spring.

- High-Frequency Use: In high-use environments such as bakeries or central kitchens, timers are operated dozens or even hundreds of times daily. High-frequency mechanical motion means faster wear. Therefore, for high-load applications, it is crucial to select a timer made of a material with a higher wear resistance rating.

4. Dust and Foreign Matter Contamination

Although mechanical timers are typically protected by an outer casing, fine particles can still enter through gaps in harsh industrial or dusty environments.

- Dust Accumulation: Once fine dust particles enter the gear train inside the timer, they act as abrasives, accelerating wear of parts and increasing operating resistance.

- Oil Intrusion: In some equipment that heats grease, oil vapor or oil contamination may intrude, contaminating the lubrication system and causing performance degradation of the mechanical timer.

Recommendations for Extending Timer Lifespan

- Choose a product that meets specifications: Ensure the temperature resistance, water resistance, and dustproof rating of the selected timer are suitable for your oven's operating conditions.

- Avoid Overuse: Operate the timer knob gently and properly.

- Perform Regular Inspection: For industrial ovens, regularly inspect the exterior of the timer for oil or dust accumulation.

As a professional supplier of oven mechanical timers, we are committed to providing mechanical timers made of high-quality, temperature-resistant materials and precision-engineered to withstand a variety of rigorous operating challenges, ensuring a longer life for your equipment.

English

English 中文简体

中文简体