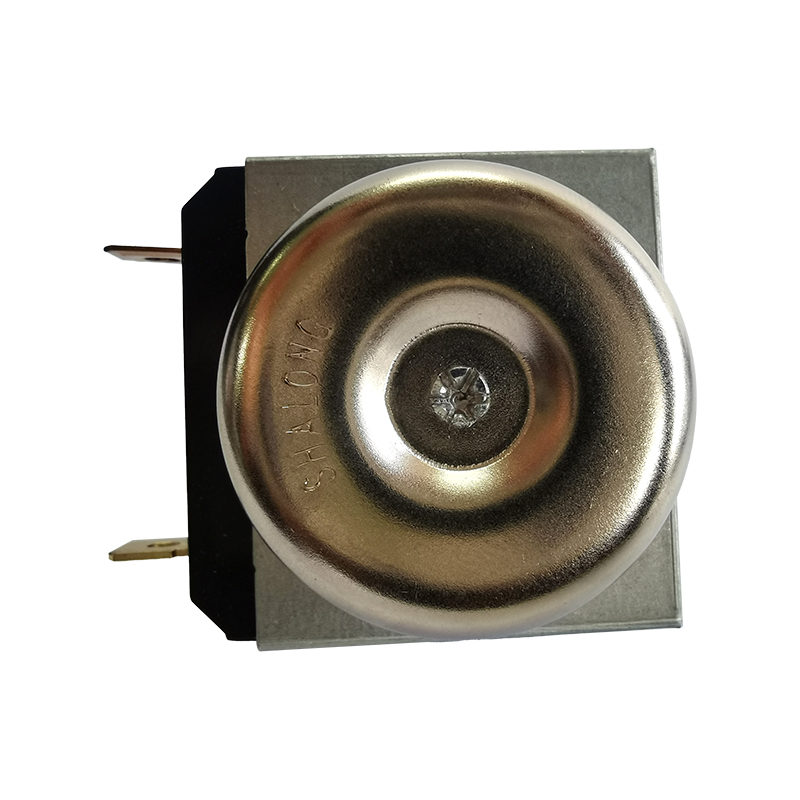

The metal mechanical timer of the disinfection cabinet adopts a precise mechanical structure design, and realizes the timing function through physical structures such as gears and springs. Under long-term high-load operation, as long as the internal parts of the timer are not seriously physically damaged or worn, its travel accuracy can usually be maintained at a high level. The timer can work accurately according to the set time without obvious deviation.

The mechanical transmission system of the metal mechanical timer is carefully designed and manufactured to ensure smooth operation under long-term high-load operation. The pointer of the timer should move evenly and continuously without jamming, pausing or jumping. This smooth running state helps to maintain the stability and reliability of the timer.

Metal mechanical timers are usually made of strong and durable materials such as metal and plastic, which can withstand high temperatures and pressures, as well as long-term physical wear. Therefore, the timer is not prone to deformation, cracking or damage during long-term use.

The internal parts and structures of the metal mechanical timer are specially treated to resist the adverse effects of aging, corrosion and oxidation. This means that the timer can maintain its original performance and function under long-term high-load operation without obvious performance degradation or failure.

The structure of the metal mechanical timer is relatively simple and easy to disassemble and clean. During long-term use, users can perform maintenance and care on the timer as needed, such as cleaning internal parts and applying lubricating oil. These maintenance measures help extend the service life of the timer and keep it in good working condition.

The timer should be placed in a stable, dry, well-ventilated environment to avoid physical damage such as impact, vibration or extrusion. Users should regularly perform maintenance and care on the timer, such as cleaning internal parts, checking the wear of gears and springs, etc. This helps to detect and deal with potential problems in a timely manner and ensure the stability and durability of the timer. The timer should avoid being in harsh environments such as humidity, dust or high temperature for a long time, which will accelerate the aging and damage of parts and shorten the service life of the timer.

English

English 中文简体

中文简体