Mechanical timers are widely used in kitchen appliances, industrial equipment, and lighting control in daily life. With prolonged use, problems such as inaccurate timekeeping, inability to keep time, or complete malfunction are inevitable. Many people then ask: Can mechanical timers be repaired? The answer is yes. Most mechanical timers can have their functionality restored and their lifespan extended through proper repair and maintenance.

Why Do Mechanical Timers Fail?

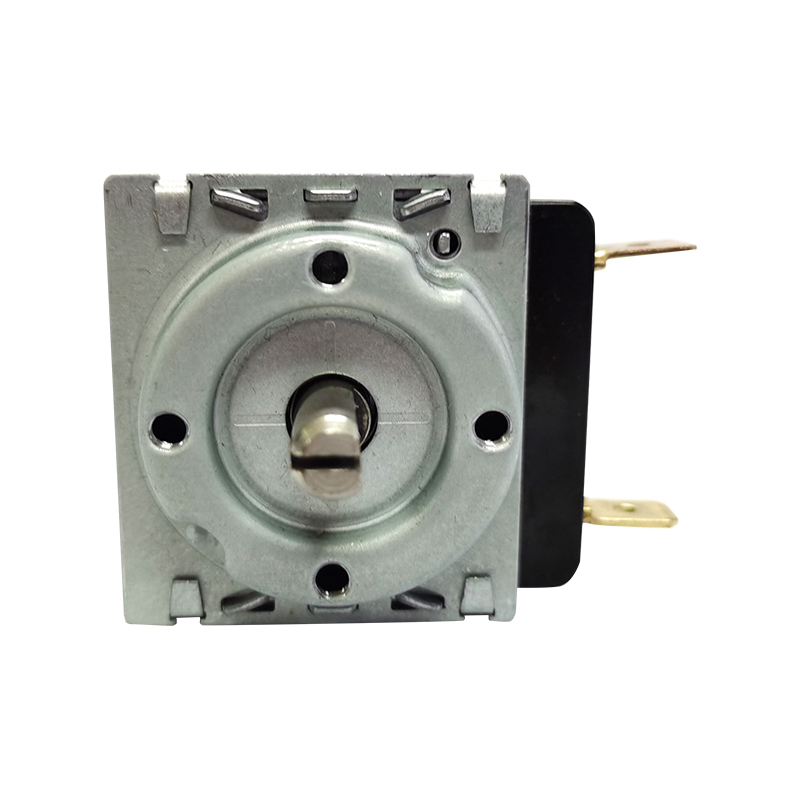

Mechanical timers rely on physical components such as a mainspring, gear train, and escapement mechanism to operate. Common causes of failure include:

Insufficient Lubrication: Increased friction in the internal gears leads to inaccurate timekeeping or jamming.

Component Wear: After prolonged use, gears and shafts may wear or deform.

External Impact: Drops or vibrations may cause internal components to shift.

Dust Accumulation: Dirt enters the mechanism, affecting its operation.

Mechanical Timer Repair Steps

Diagnosing the Problem: First, check the appearance of the mechanical timer and the resistance of the knob to initially determine the fault location.

Disassembly and Cleaning: Carefully disassemble the casing and use professional tools to clean the gears and springs, removing rust and dirt.

Lubrication and Adjustment: Add an appropriate amount of watch oil to the moving parts to ensure smooth gear engagement.

Parts Replacement: If severely worn gears or springs are found, contact the manufacturer or a professional repair shop for replacement.

Assembly and Testing: After reassembly, rotate the knob several times to test if the timing function is restored.

Self-Repair or Professional Help?

For simple cleaning and lubrication, users can attempt to handle it themselves. However, for delicate parts, it is recommended to have it handled by a professional repairman to avoid further damage. Many older Mechanical timers have classic designs and relatively interchangeable parts, resulting in a high success rate of repair.

Maintenance Recommendations: Extend the Life of Mechanical Timers

Avoid humid environments and high-temperature exposure.

Use at least once a month to prevent the lubricant from hardening.

Operate the knob gently, avoiding forced twisting.

Mechanical timers can not only be repaired, but often continue to work reliably for many years after repair. Regular maintenance and timely repairs are key to keeping these practical devices in service.

English

English 中文简体

中文简体